Elastomeric Roof Coatings - What You Need to Know

Elastomeric Roof Coatings

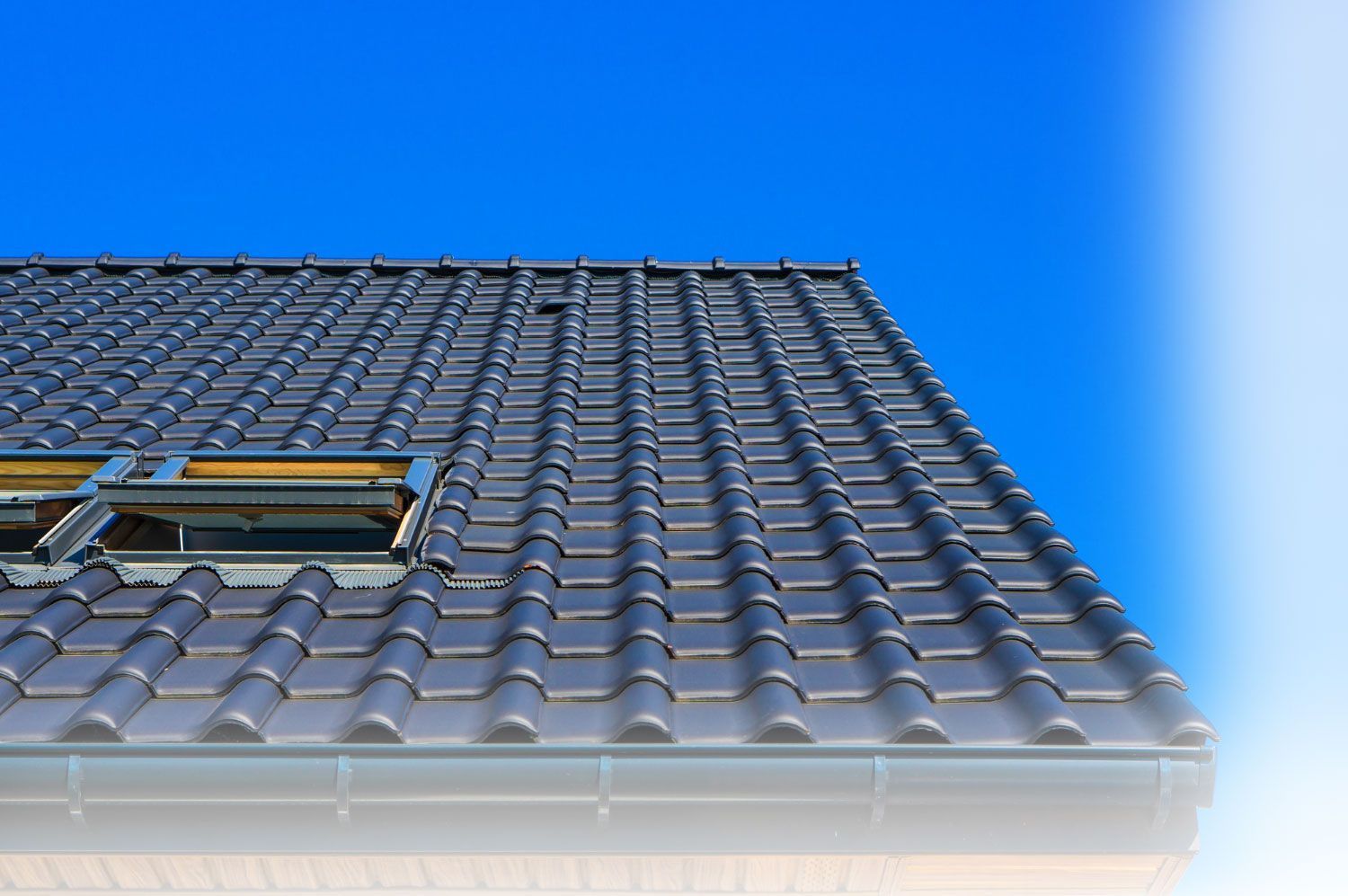

Are you keen on reducing your energy expenses and addressing leaks in your commercial roofing system? If so, delving into the realm of elastomeric roof coatings is a wise move. In essence, elastomeric roof coatings stand out for their remarkable durability and capacity to shield your roof from leaks and other forms of damage. These coatings possess the unique ability to stretch and adapt alongside your roof, accommodating expansions and contractions prompted by temperature fluctuations.

Moreover, the highly reflective nature of elastomeric roofs serves as a boon, particularly in regions like Dallas - Fort Worth Metroplex where scorching summer temperatures can drive cooling costs through the roof and strain HVAC systems.

If you've been contemplating replacing your commercial roof due to age-related concerns, reconsideration may be in order. Opting for an elastomeric roof coating can save you money while restoring your roof to its former glory. Let's delve deeper into everything you need to know about elastomeric roof coatings.

Understanding Elastomeric Roof Coatings

An elastomeric roof coating is akin to a paint-like liquid utilized in commercial roofing systems. This substance forms a protective membrane atop existing roofs, offering a myriad of benefits including:

- Forming a monolithic layer

- Rendering the roof waterproof

- Prolonging the roof's lifespan

- Extending the roof's warranty

- Enhancing reflectivity, thereby curbing cooling expenses

Typically, these coatings boast a white hue to reflect sunlight and maintain comfortable temperatures in hot climates. However, in colder climates, property owners might opt for gray coatings to absorb heat during chilly months. Elastomeric coatings possess numerous desirable properties such as chemical resistance, abrasion resistance, tensile strength, tear strength, hardness, and elongation. Blending these properties can result in a robust roof system, compensating for any deficiencies in the membrane itself.

Comprised of polymers, elastomeric roof coatings create a waterproof and weatherproof seal on roofing systems. For those grappling with aging yet structurally sound roofs, applying an elastomeric roof coating presents an enticing alternative to full-scale roof replacement. By doing so, superior protection is afforded to your building without the inconvenience and expense associated with stripping off the old roof, allowing business operations to proceed uninterrupted during the coating application process.

Exploring the Four Main Types of Elastomeric Roof Coatings

Elastomeric coatings come in a diverse array of formulations, each tailored to specific surfaces and environmental conditions. The primary types include silicone, polyurethane, acrylic, and butyl.

- Silicone: Ideal for flat roofs due to their ability to withstand pooling water, silicone coatings are renowned for their resilience and weathering capabilities.

- Polyurethane: Recognized for durability, polyurethane coatings are suitable for roofs subject to heavy foot traffic and ponding water. They effectively withstand temperature fluctuations and are well-suited for TPO, PVC, and modified bitumen roofs.

- Acrylic: Water-based and ideal for sloped roofs, acrylic coatings offer affordability and environmental friendliness. However, they are not conducive to pooling water and entail evaporation losses during application.

- Butyl: Boasting exceptional flexibility and impermeability to air, butyl coatings excel on asphalt built-up, modified bitumen, and single-ply roofing systems. While environmentally less friendly, they offer robust protection against weather elements.

How Elastomeric Roof Coatings Function

Derived from polymers with large, amorphous molecules, elastomeric roof coatings effectively prevent existing roof damage from exacerbating and seal roof leaks. Upon application, the coating components form a resilient membrane, seamlessly integrating with the surface and enhancing water resistance and durability.

Evaluating the Longevity and Maintenance of Elastomeric Roof Coatings

The longevity of elastomeric roof coatings typically spans between ten to twenty years, contingent upon several variables such as coating thickness. Regular inspections are integral to maintaining roof health, enabling prompt detection of issues before they escalate. Despite exposure to rain, wind, foot traffic, or falling debris, elastomeric roof coatings boast robust resilience, thanks to their elastic properties.

Selecting a Commercial Roof Coating: Six Crucial Factors

When selecting a roof coating, consider factors like elongation, permeability, tensile strength, reflectivity, solids by volume, and emissivity. These properties influence the coating's flexibility, moisture resistance, durability, energy efficiency, thickness, and heat emission, respectively.

Cost Considerations for Elastomeric Roof Coatings

The cost of coating a roof with elastomeric coatings varies based on the selected type. Acrylic coatings are the most economical but necessitate more material due to evaporation losses. Conversely, silicone, polyurethane, and butyl coatings offer higher durability at varying costs.

Seeking Elastomeric Roof Coating Services in Dallas - Fort Worth?

Elastomeric roof coatings offer a cost-effective solution for enhancing roof protection and energy efficiency. For top-notch roofing services in Atlanta, trust Colony Roofers. With a commitment to exceptional customer service and competitive pricing, we ensure unparalleled quality in every project. Contact us today to schedule an estimate or address any queries regarding the roof coating process or other roofing needs.